REVOLUTIONARY WIDE RANGE OF ADVANCED PAPER CORRUGATED BOARD & BOX MAKING MACHINES

We Take Pride in Building The best Corrugate Equipment in the Industry.

Today Technical Innovation And Change On the Corrugators is So Rapid That Even A Relatively Recent Installation can Quickly Become Out of date.

HIC Now Offers A wide Range of Paper Corrugated boards & box-making Machines. Which Enables the User to bring Each unit up to The most recent Technological Trends in India.

INDIA'S FASTEST ADVANCED PAPER CORRUGATED BOARD & BOX MAKING MACHINES

- DF-40 DUAL FLUTE HIGH SPEED SINGLE FACER PAPER CORRUGATED BOARD MAKING MACHINE

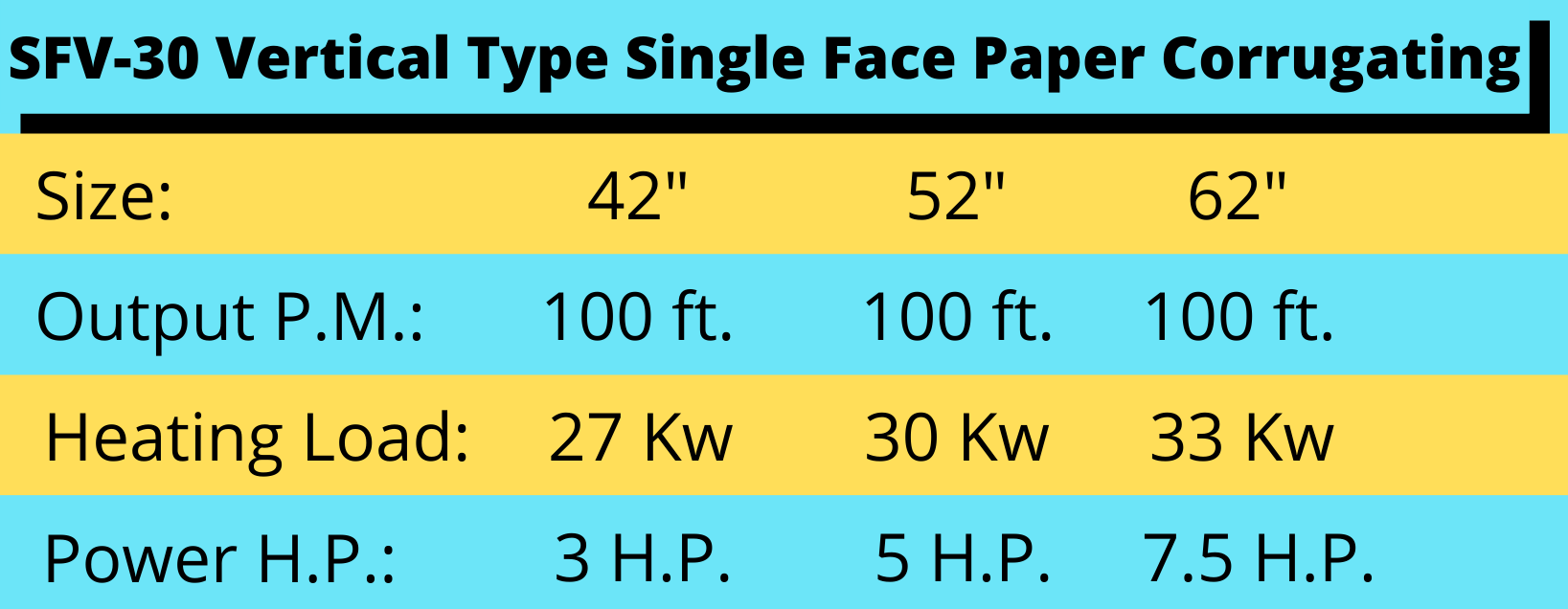

- SFV-30 VERTICAL TYPE SINGLE FACE PAPER CORRUGATING MACHINE BEARING MOUNTED

- SFO-40 OBLIQUE TYPE SINGLE FACE PAPER CORRUGATING MACHINE BEARING MOUNTED

- RS-70 ROTARY SHEAR

- HBC BOARD CUTTER

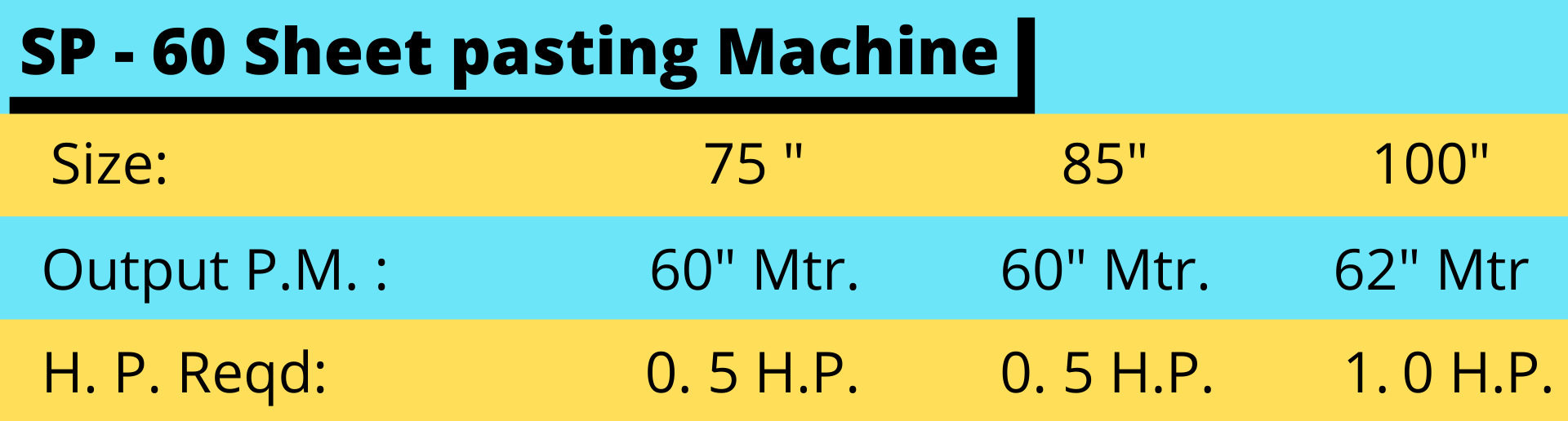

- SP-60 SHEET PASTING MACHINE

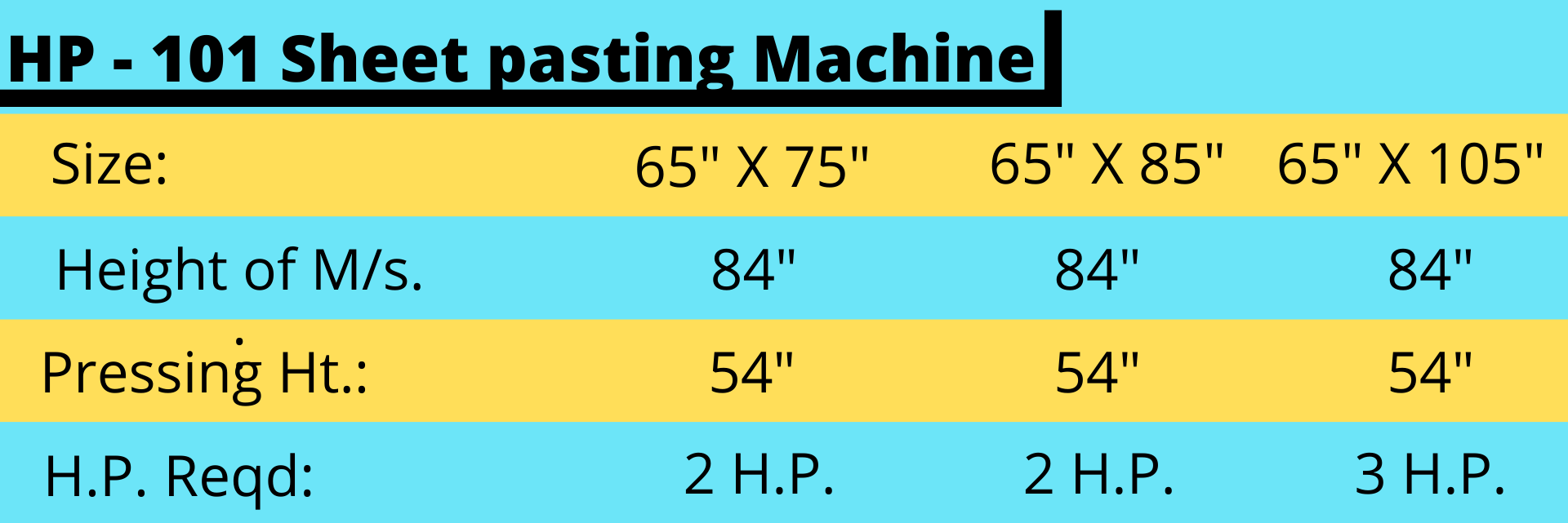

- HP 101 SHEET PRESSING MACHINE

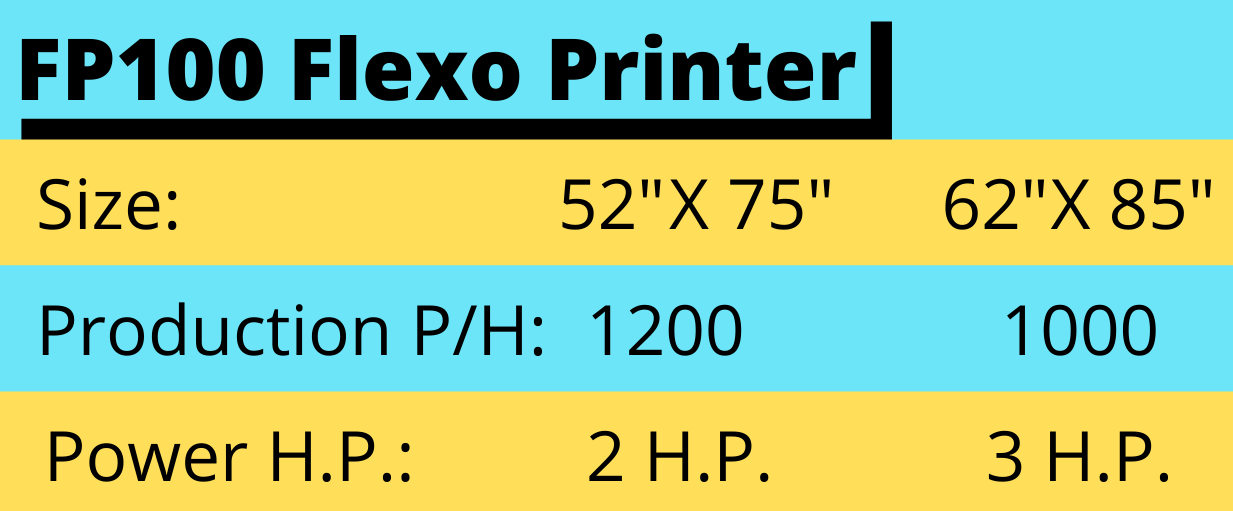

- FP 100 FLEXO PRINTER

- FRC 100 4- BAR ROTARY SLITTERING & CREASING MACHINE

- ES30 ECCENTRIC SLOTTER

- RS 4 SEMI AUTO ROTARY SLOTTING MACHINE

- DC 20 DIE-CUTTING, EMBSSING & CREASING MACHINE

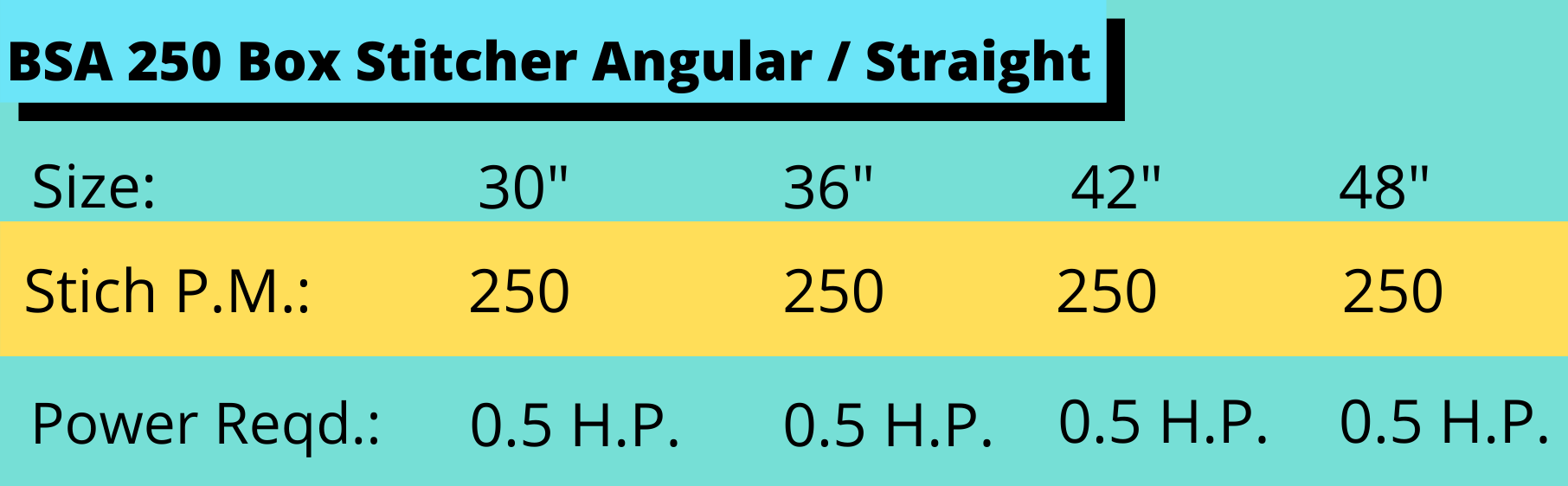

- BSA 250 BOX STITCHER ANGULAR / STRAIGHT

PRODUCTS DETAILS

In the Machines, The Single Face Web, After An Application Mechanism had Applied Adhesive to the Flute Tips, was Brought Into Contact With the Double _face Liner At the entry of The Machine

And The Combined Webs Drew Over A Series Of Heated Plates By an Arrangement Of Top. And Bottom Heavy woven Cotton Belts.

Immediately Following The Hot plates Section Was a tractor, COOLING – tempering Section Where The combined Web Was Supported By a bottom Belt Carried on a bed Of Idlers.

Both Top and bottom belts were Powered By a pair of Driven Puller Roll at the rear of the Machine.

The belt, Ballasted By A series Of Idlers, Extended The Full Length Of The Machine. Over the Healing Section, this Arrangement Kept the corrugated Web In intimate Contact With the heated Plates,

providing for Good heat transfer and holding the single Face web and The Bottom liner infirm.

We have Developed a 3PLY & 5PLY Paper Corrugated

Which Offers The Best HIC Quality & Productivity with a productions Speed up to 50 mts. & 60 mts & 100mts per min.

The DF 40 Single Facer is a bold new Design, It Offers a High rate of production & Enhanced Efficiency. The rolls are mounted on roller bearing for S moot running & longer life Minutely Finished Flute Rolls Result In perfect Formation of flutes, Recirculating oil lubrication system based on high-temperature fluorinated grease. Two pre -Hydraulic Lifting reel Stand with Double Arms Lifting and Twin Unwinding Shaft for paper reels are provided with DF-40

The DF 40 Single Facer is a bold new Design, It Offers a High rate of production & Enhanced Efficiency. The rolls are mounted on roller bearing for S moot running & longer life Minutely Finished Flute Rolls Result In perfect Formation of flutes, Recirculating oil lubrication system based on high-temperature fluorinated grease. Two pre -Hydraulic Lifting reel Stand with Double Arms Lifting and Twin Unwinding Shaft for paper reels are provided with DF-40

DF 40 UNIQUE SLIDE ROLL SYSTEM

Fast: This System Allows a Complete Roll change in less than 30 minutes. Rolls are Removed & Replaced Automatically to allow the plant to meet the customer needs without excessive downtime.

Simple: Once the Roll Cartridge is in Place there is no Adjustment to be made and no fine Tuning is Required.

Safe: Even When the rolls are hot, the foolproof design of Cartridge roll Change can be Routinely & Safely Accomplished, Even By Fewer Experience crews.

The Quick Flute Change Capability Allows The Box Plant Greater flexibility in Scheduling as well as The Ability to offer the Customer Whatever Flute Profile he needs.

This high-speed Single Facer For Making 2PLY board Offers A high Rate Of Production & Enhance Efficiency. The Rolls are Mounted on the roller on Roller Bearings.

For smooth Running Longer Life Minutely Finished Flute Rolls Result In Perfect Formation of Flute. Helical Gear Box is Provided directly Attached With The Roller By Chain.

This High-Speed Single Facer Offer’s a high rate of Production & Enhanced Efficiency.

The Rolls are Mounted on roller bearing for Smooth Running & longer Life, Minutely Finished Flute rolls Result in perfect Formation of Flutes.

Hydraulic Lifting Reel Stand Is Provided directly Attached with the Roller By Chain.

High-Speed Reels to Sheet Cutter as well as 2 Ply Corrugate Board.

This machine Can be operated in Alignment With Corrugating Machine Instead of Rewind & making Rolls On a Single Facer.

Frequency drive & A.C. induction motor one for cutting section & other for feeding section duly synchronized with the help of heavy duly electrical control panel PLC controlled complete in all respects.

Single shaft manual reel stand with brake and pulley for paper.

Heavy duty hand Operated machine To cut the Paper or corrugated board.

Hand-fed Sheet Pasting Machine Is Useful for gluing Fluted Side of the board for making 3/5/7 PLY Corrugated board.

Sheet Pressing Machine is used for pressing of Corrugated Sheet.

Glued Sheets Which Are Then Processed On Pasting Machines are piled on a lower plate & then pressure is Applied For Some Time By Lowering Upper moving plates.

For Printing Kraft Paper & Corrugated Boards Distinct & Precise Impression, Instant Drying, Extremely Simple To Operate, Easy Accessibility for Cleaning.

This is useful for Creasing And Cutting Simultaneously. The Machine Is with Two Pairs of Shaft. For Easy Feeding Two Guides, Sets Of Creasing dies & 4 Sets Of S littering Dies Are Provided.

Slotting & Corner Cutting Is done Simultaneously Over this Machine.

It is Capable of Slotting a Number Of Sheets In One stroke.

The Distance Two Slots and Slot Depth Is Adjustable.

Two Guides Are Provided To Facilitate Easy Feeding & correct Dimension.

This Machine can Perform Slotting, Corner Cutting, Creasing, Slicing at the Same Time. Its main Features of Single Sheet Sending, Widely Usage.

Characteristics:

1. IT Adopts The Chain Paper- feeding.

2. Adopt Planet Style Digital Electrical Adjustment of 360 Degrees.

3. Adjust Height of Carton Synchronous ( means adjust four slotting knives together) With Electronic Counter for record Production Quantity.

4. Equipped with Speed Variable Motor & Controller.

5. Good Quality Cutter Be Processed With Heat – Treatment.

This Heavy Duty Platen Die Cutter Press Is Meant For Creasing, Cutting & Punching Of Card Board as well as corrugated boxes. the Machine Is Provided with Safety Devices Like Electro-Magnetic Clutch, Timer, Brake, Trip Bar & Safety.

The machine is also Equipped With Micron Impression Adjustment System, Dwell Timing Device, Centralized Lubricating System, Sheet Counter, and All Standard Accessories.

To Stitch The Card Board & Corrugated Board Boxes.

PROJECT MISSION

HIC Machinery Co. want To see ‘ Make in India‘ Become an Internationally Respected label.

Our Machine Are Dedicated To our Commitment to make this Happen.